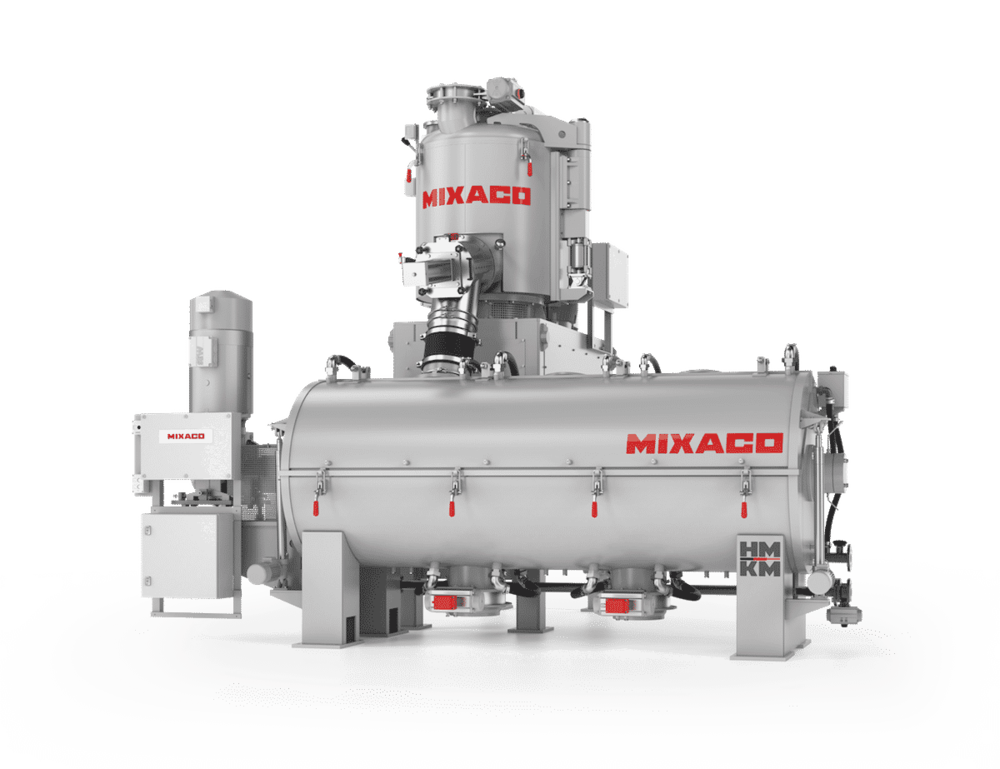

Heating/Cooling Mixer. For throughputs up to over 8,000 kg/h. Our heating/cooling mixer is the optimal solution when it comes to demanding mixing tasks.

It guarantees fabulous product preparation in heating and high efficiency in cooling performance.

Benefits at a glance. Fast mixing – fast cleaning.

It guarantees fabulous product preparation in heating and high efficiency in cooling performance.

Benefits at a glance. Fast mixing – fast cleaning.

- Can be used for different applications such as heating, agglomerating, bonding

- Process-optimized tools that can be changed quickly

- Integrated aspiration with targeted air flow guarantees optimal evacuation of dust and moisture particles

- Heating mixers are always double-walled

- No formation of deposits in PVC formulations with hygroscopic stabilizers – prevents defects on extruder and end product

- Full insulation of heating mixers possible

- Vertical heating-cooling mixer for throughputs up to 2,500 kg/h

- Horizontal heating-cooling mixer for throughputs up to > 8,000 kg/h

- Performance-optimized selection of mixer drives for high energy efficiency

- Innovative aspiration for optimum dehumidification of the mixture

- Extensive range of additional equipment for individual adaptation to customer requirements

- ATEX versions possible

MIXACO Heating/Cooling Mixer for PVC/WPC/SPC/Plastics

Clearly arranged control panel.

Operating Modes

Manual mode

Automatic mode

Cleaning mode

Process parameters

Mixing parameters

Mixing time

Mixing tool speed

Current consumption mixing drive

Torque (optional)

Liquid injection (optional)

Process visualization

System status

Process parameters

Machine setting

Error management